DC SUSTAINABILITY

DISTRIBUTION CENTERS

HUMAN HEALTH - LEVEL 3

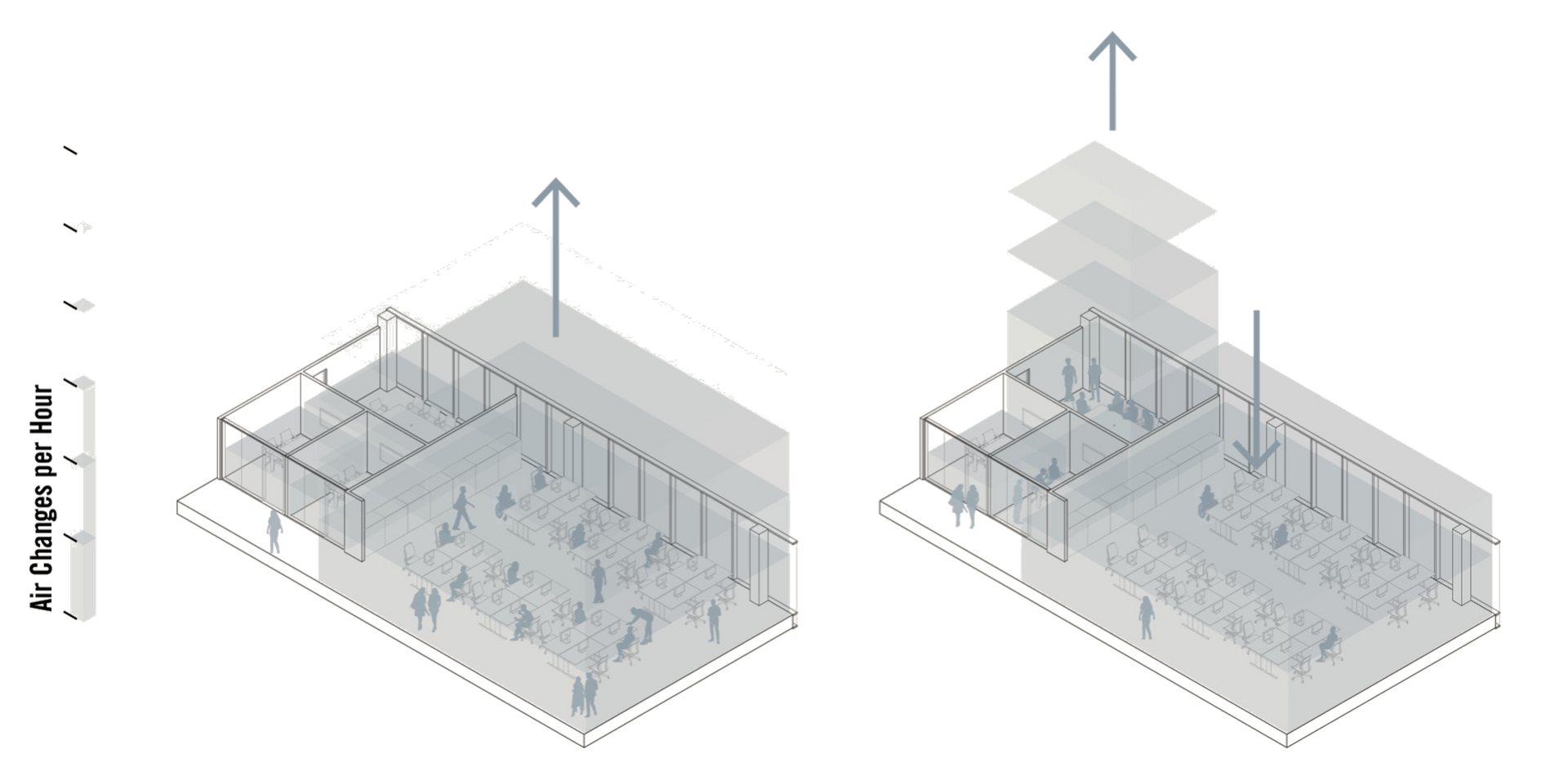

Minimum Indoor Air Quality Performance

- Comply with LEED prerequisite Minimum Indoor Air Quality Performance by meeting the requirements for both ventilation and monitoring, even if not pursuing LEED certification

- Ventilation

- Meet the minimum requirements of ASHRAE Standard 62.1-2010, Sections 4-7, or a local equivalent, whichever is more stringent

- Projects outside the U.S. may instead meet the minimum requirements of CEN Standards EN 15251-2007 and EN 13779-2007

- Monitoring

- Monitor the outdoor air intake flow per LEED prerequisite requirements

Outdoor Airflow

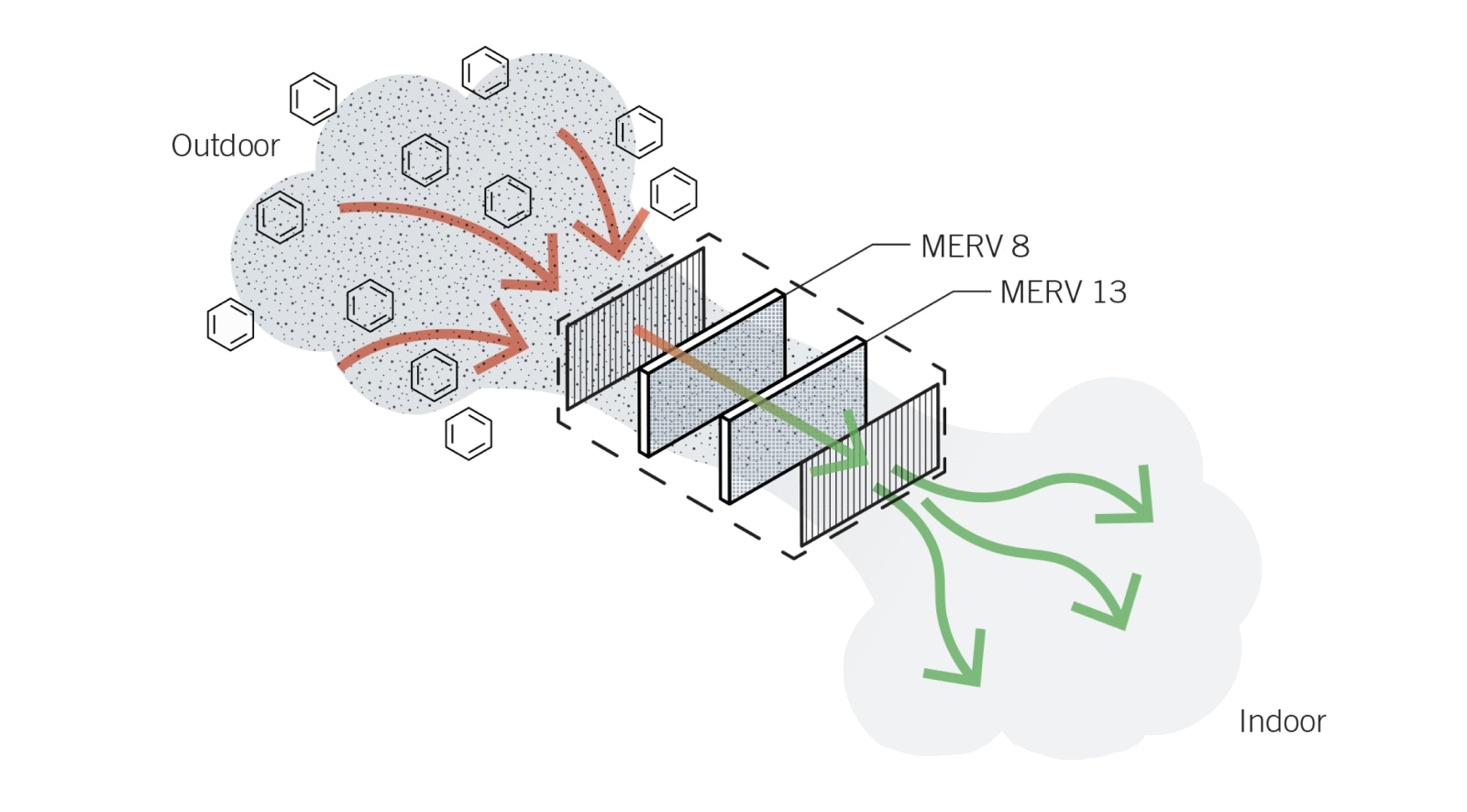

- Air Filtration

- Include air filters in ventilation systems with a MERV 8 (pre-filter) during construction and MERV 13 (final-filter) prior to occupancy or include Class F7 or higher air filters as defined by CEN Standard EN 779-2002, Particulate Air Filters for General Ventilation

- If pursuing LEED certification, filtration can contribute to LEED credit Enhanced Indoor Air Quality Strategies

- Recommend sizing the outdoor air ventilation system such that additional filter bank space is available for carbon filters which can be inserted to treat the air supply during wildfire conditions

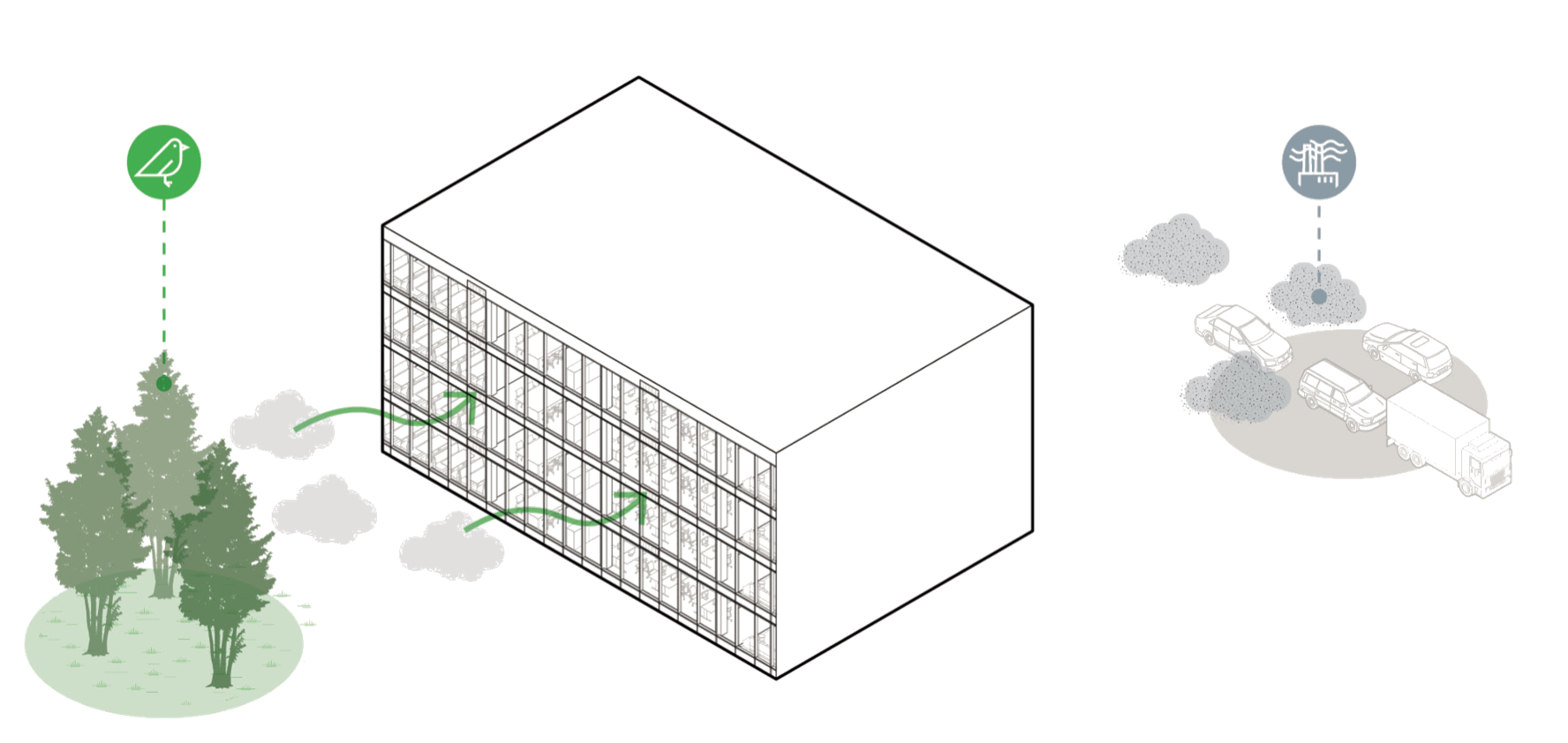

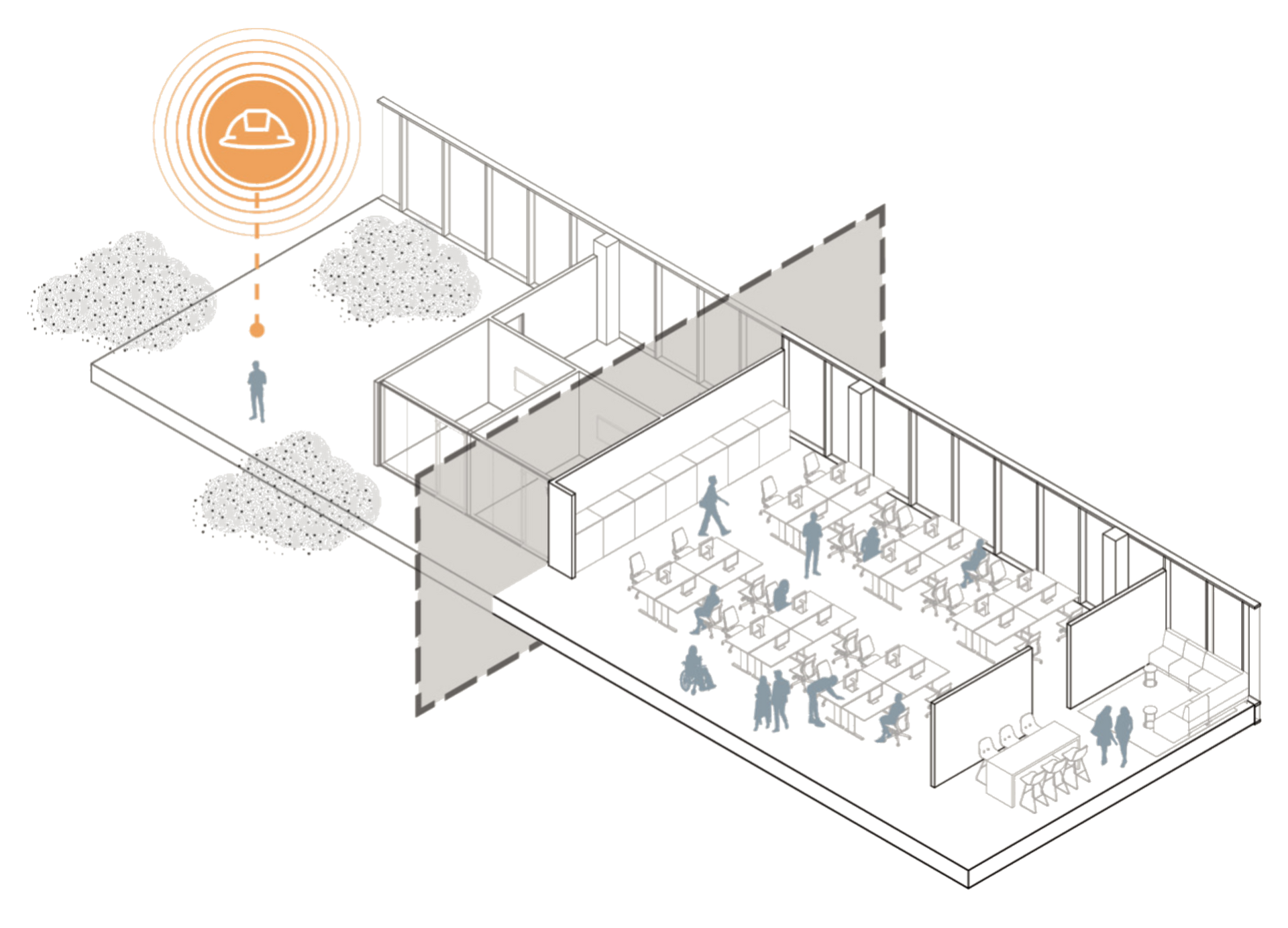

- Air Intakes

- Building outdoor air intakes should be located away from localized pollutant sources (e.g., highways, trash areas, congested roadways, parking garages, car idling, restaurant kitchen exhaust)

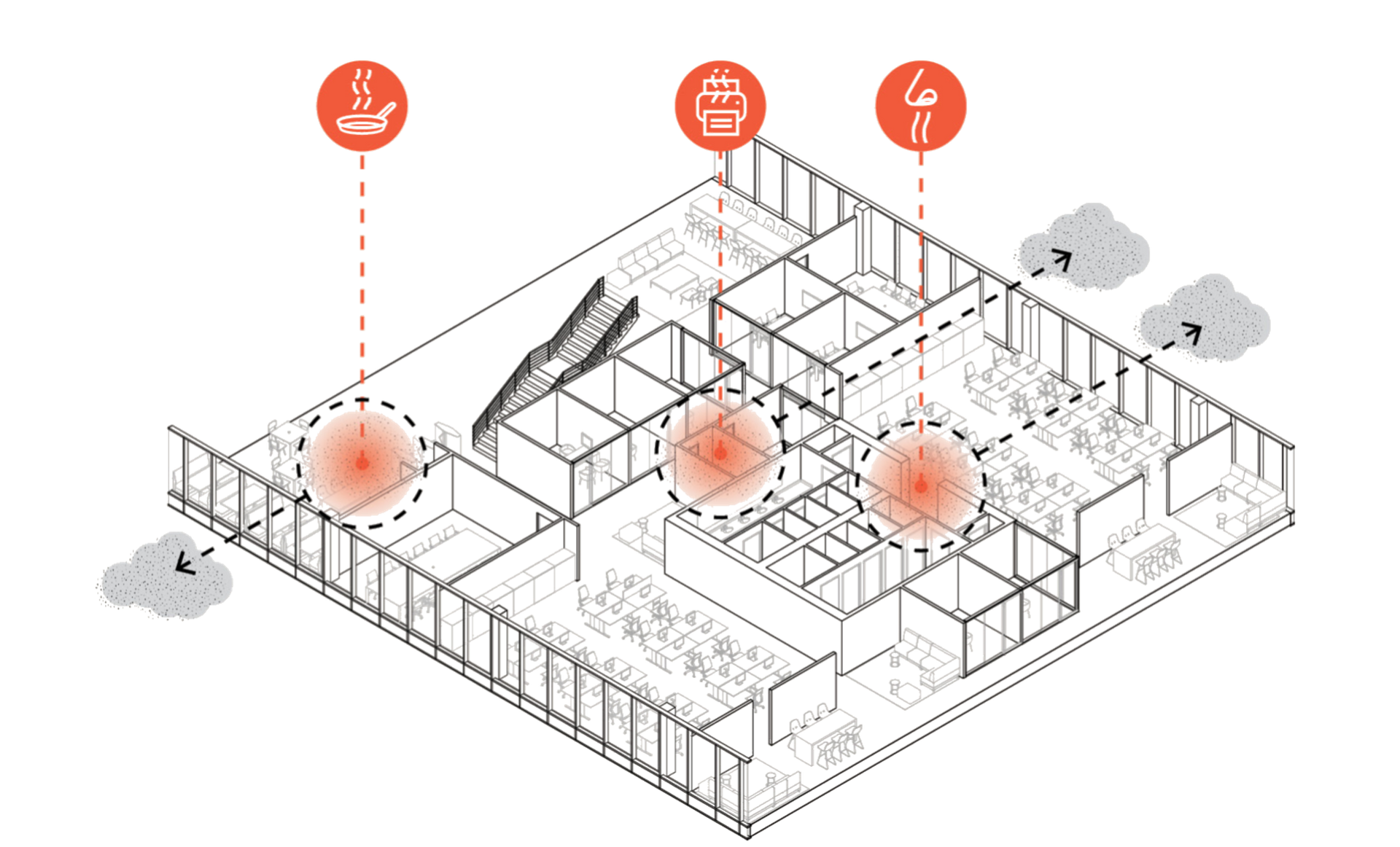

Exhaust

- Provide a dedicated exhaust fan in all areas with high level of contaminants (kitchen, printing, copy, janitor, etc.)

OPTIONAL: Recirculated Air

- Recommend that each ventilation system that supplies recirculated air to occupied spaces have MERV 13 or equivalent filtration media class

No Smoking

- Prohibit smoking inside the building

- Prohibit smoking outside the building except in designated smoking areas located at least 25 feet from all entries, outdoor air intakes, and operable windows

- Provide smoke-free signage at all entrances and outdoor areas

OPTIONAL: Demand Control Ventilation (DCV)

- Monitor CO2 concentrations within all densely occupied spaces according

- Provide DCV to maintain CO2 levels at or below 800 ppm

- Add in-room CO2 monitoring for control signal to BAS and building automation programming for DCV by zone

NOTE:

DCV may not be easily achieved in all projects depending on the base building’s HVAC system. Project teams may need to evaluate the feasibility and cost impact for this measure in existing buildings.

Construction Indoor Air Quality

- Comply with LEED Construction Indoor Air Quality Management Plan requirements or a Nike-approved equivalent

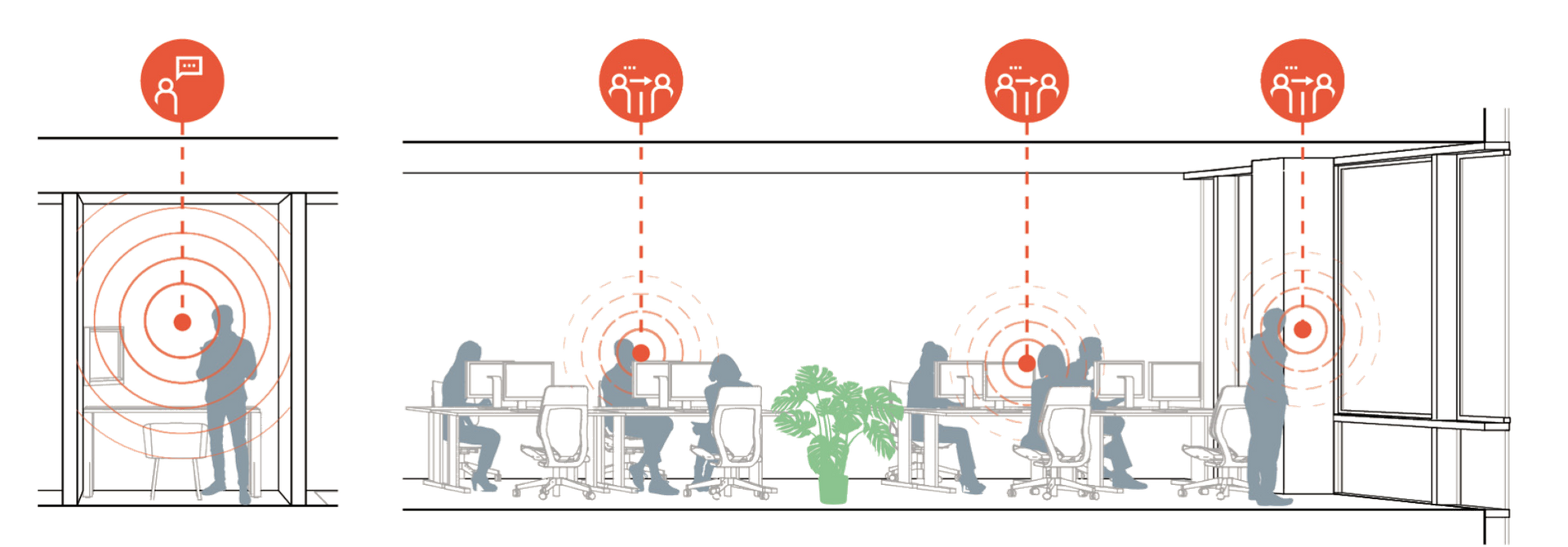

Sound Reduction

- Encourage voice modulation by removing partitions at workstations

- Create organization of open office space that discourages workstation partitions. If workstation partitions are required, they should allow for open office occupants to have visual connections while seated

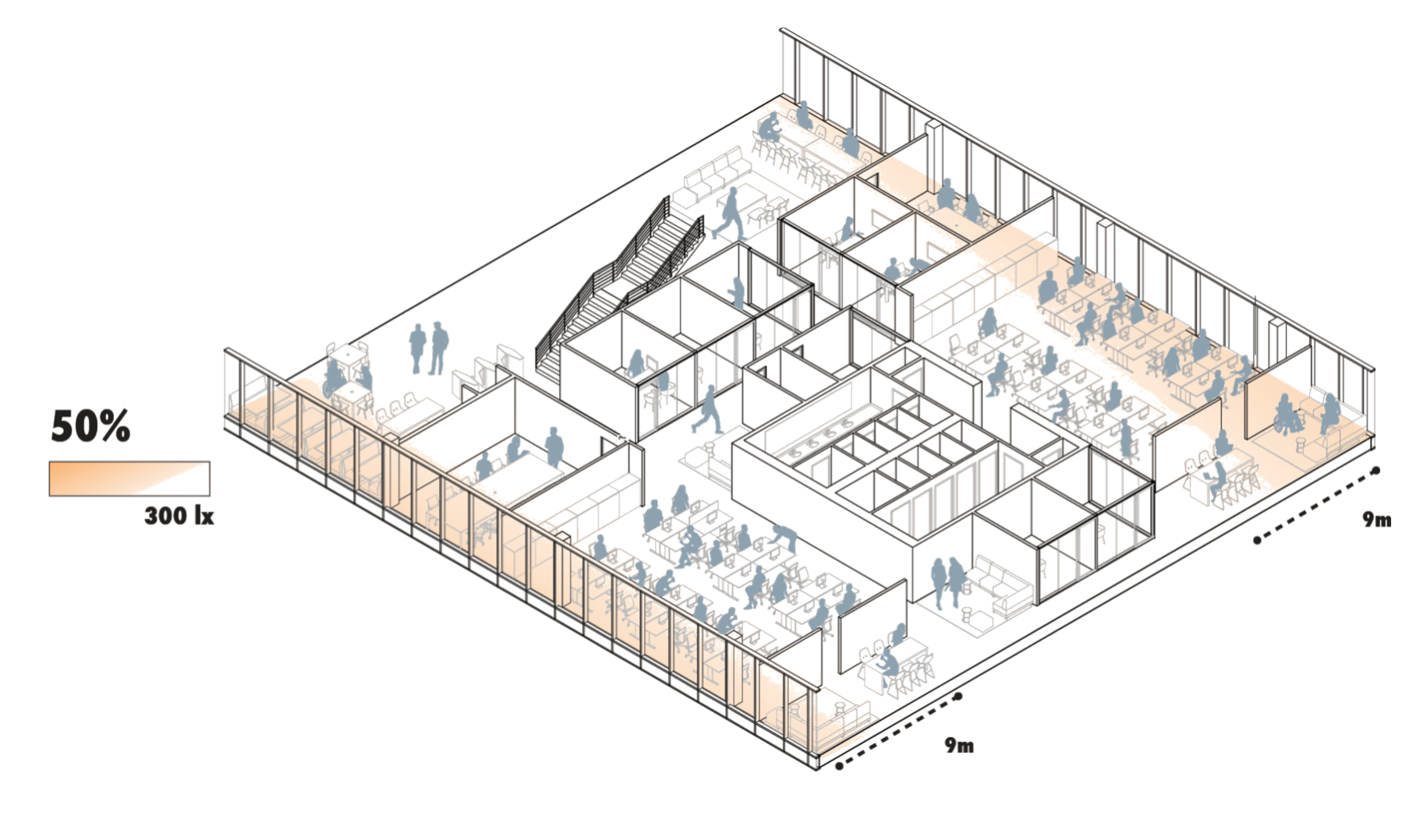

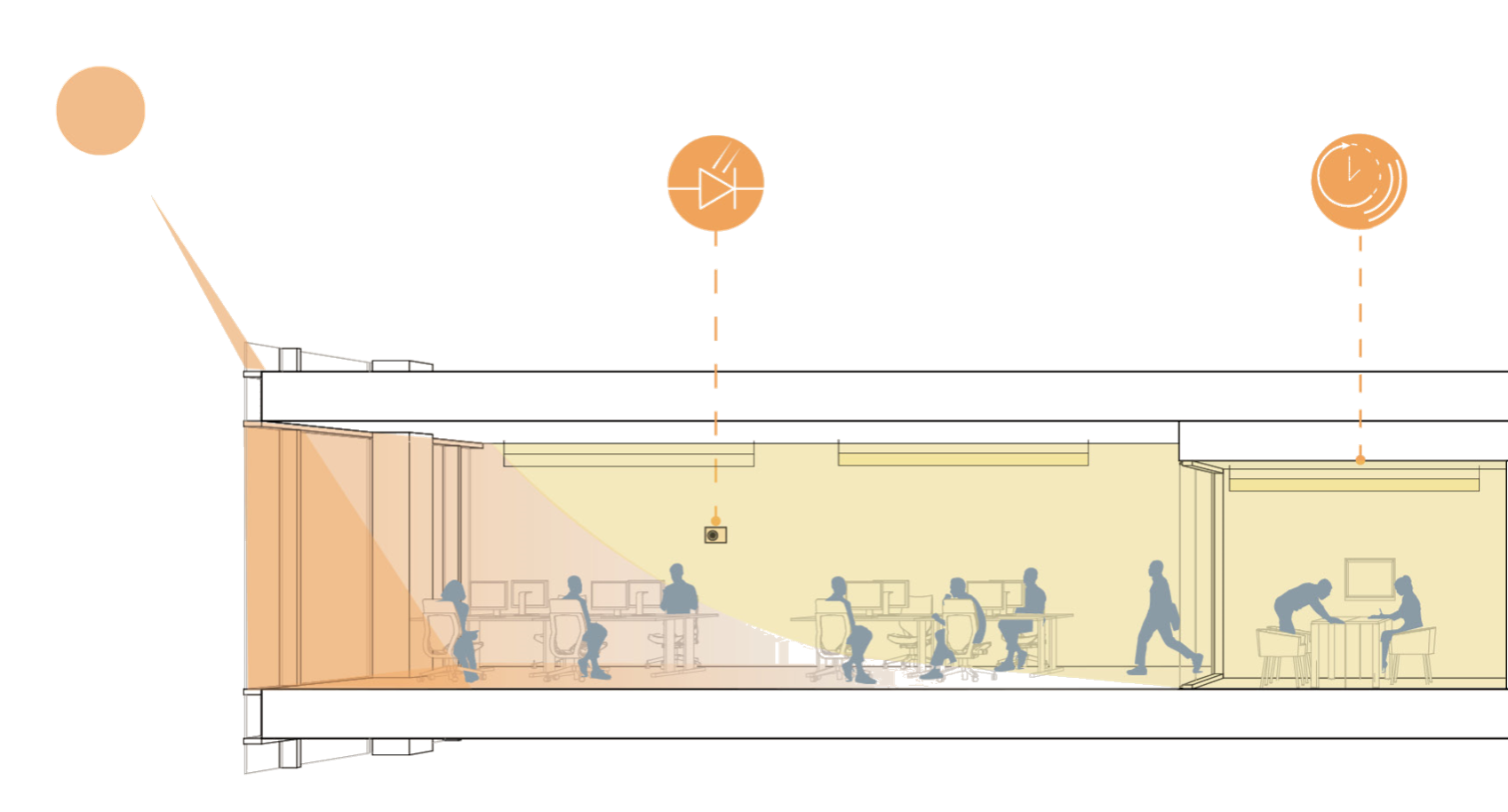

OPTIONAL: Daylight

- Maximize visibility to natural light in the building design by prioritizing open workspaces

- Provide access to daylight for building occupants with a Spatial Daylight Autonomy (SDA) of 300 lux for 50% between the hours of 8am-6pm annually

- All workstations should be located within 9 meters of a window and SDA requirement provided to 45% of regularly occupied floor area

- If pursuing LEED certification, this can contribute to LEED credit Daylight. Note that a daylight model will be required to demonstrate compliance with the LEED requirements which are more stringent than the above best practices

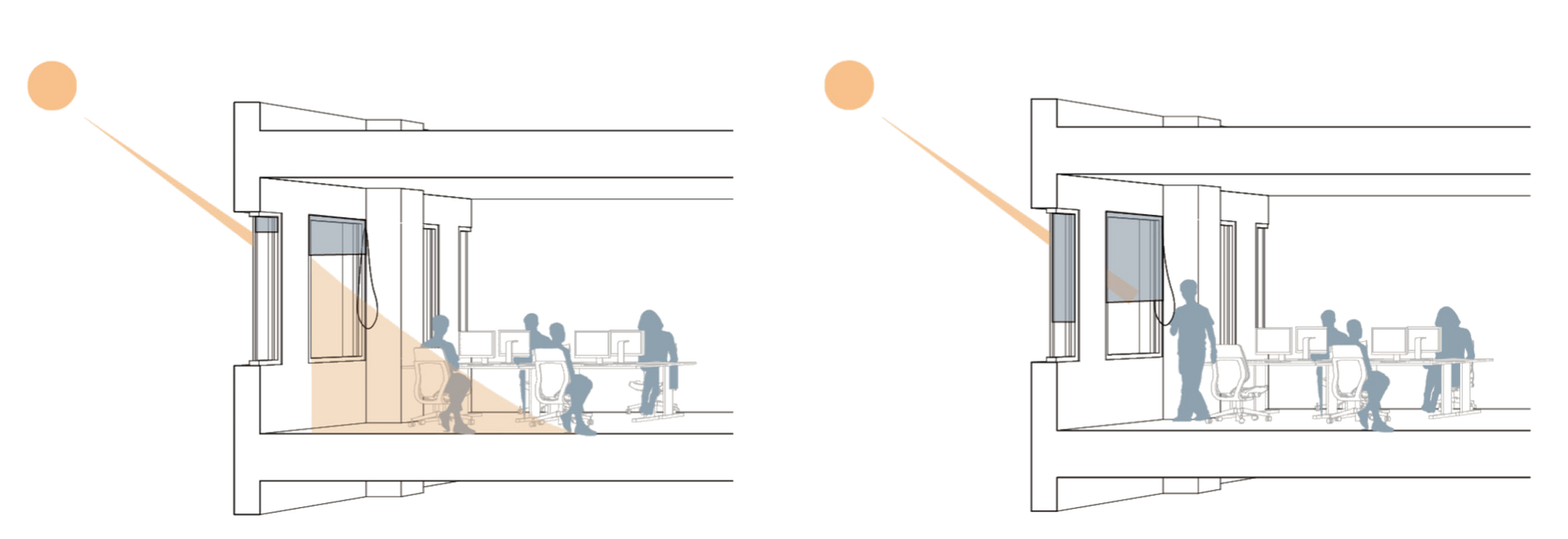

Glare Protection

- Provide manual shades on all windows that experience direct solar radiation or provide adjacent workstations with personal glare protection

- Light sources should be shielded and diffused. Minimize the use of reflective surfaces.

Lighting Controls

- Enable preset scenes in enclosed rooms

- In enclosed rooms, controls should be adjacent to doors

- Group lighting controls with AV, thermostat, etc. when possible

- Dimmers and controls must be simple and intuitive

- Dimmers should set a high trim for maximum brightness. Designers should target high end trims to be no less than 80% of full output.

Lighting Quality (in non-warehouse spaces)

- All indoor and outdoor spaces comply with the illuminance thresholds specified in one of the following reference guidelines:

- IES Lighting Library, Lighting Applications Standards Collection

- EN 12464-1:20214 or EN 12464-2:2014

- ISO 8995-1:2002(E) (CIE S 008/E:2001)

- GB50034-2013

- CIBSE SLL Code for Lighting

- All luminaires within regularly occupied spaces (excluding wall wash fixtures, concealed fixtures, emergency lighting and decorative fixtures) meet one of the following requirements when measured at light output representative of regular use conditions:

- 100% of light is emitted above the horizontal plane

- Classified with Unified Glare Rating (UGR) of 16 or lower

- Luminance that does not exceed 6,000 cd/m2 at any angle between 45 and 90 degrees from nadir

- Ambient lighting in all regularly occupied spaces meets at least three of the following requirements:

- Horizontal and vertical luminance contrast ratios for an ambient light system is no more than 10:1 between adjacent independently controlled zones

- Illuminance uniformity ratio of at least 0.4 or 1:2.5 (minimum light level: average light level) is achieved on any horizontal task plane within a space

- One of the following:

- A lighting automation system is in use and automatic changes in lighting characteristics, such as light levels, changes in color and distribution take place over a period of at least 10 minutes

- A lighting automation system is not in use

- The Correlated Color Temperature (CCT) in each room for similar fixtures is consistent (±200 K) at any point of time.

- All luminaires in occupiable spaces (except decorative fixtures, emergency lights and other lighting for signage) meet at least one of the following color rendering requirements. If tunable white lighting is used, the requirements are met at 1000 K intervals from the lower end (with a minimum of 2700 K) to the higher end (with a maximum of 5000 K):

- CRI (Ra) ≥ 90

- CRI (Ra) ≥ 80 and R9 (R9) ≥ 50

- IES Rf ≥ 78, IES Rg ≥ 100, -1% ≤ IES Rcs,h1 ≤ 15%

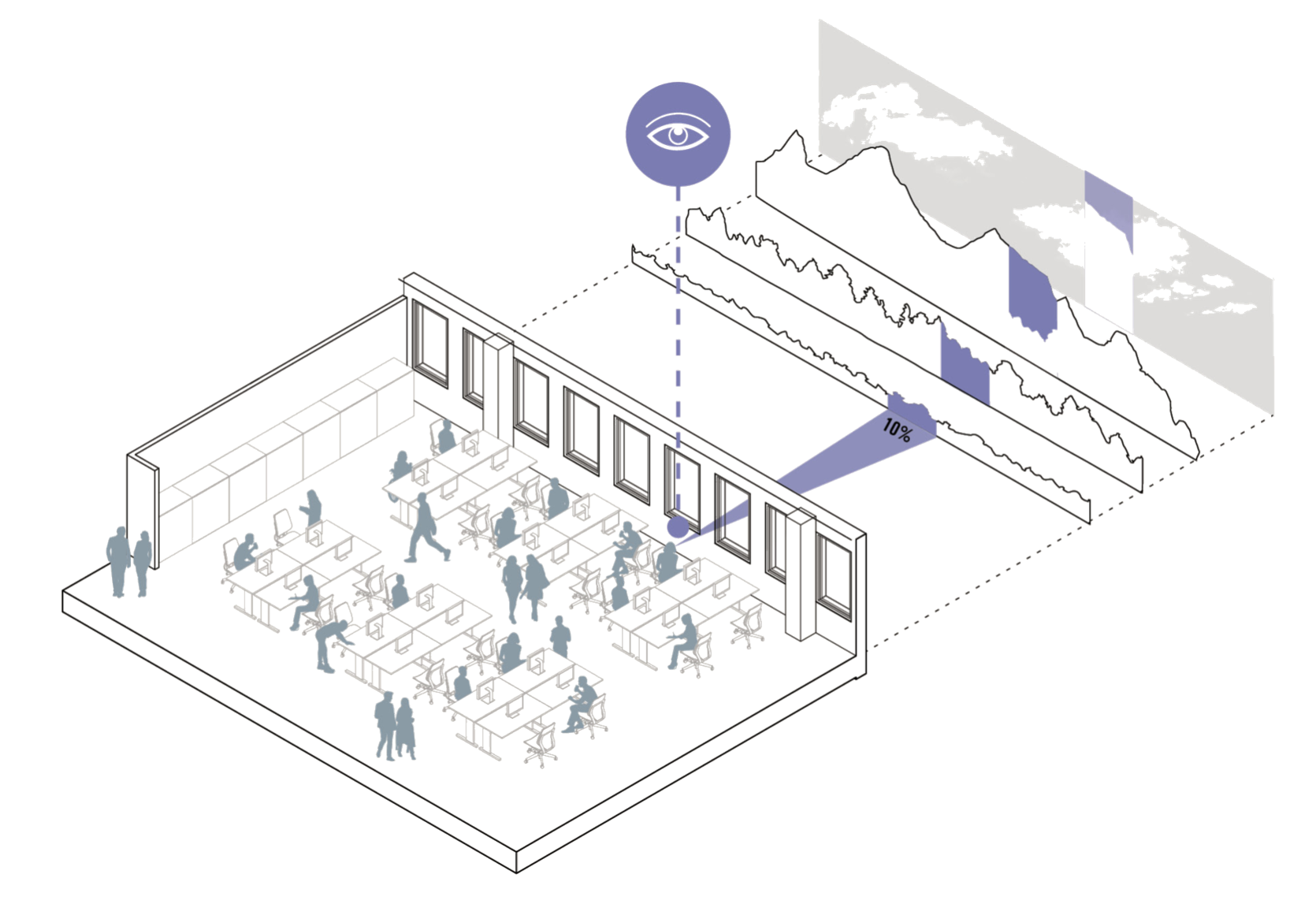

Views

- Provide access to views for as much of the regularly occupied are as possible (aim for a minimum of 90% of the workstations)

- Views must include access to nature, urban landmarks, art or objects at least 25 feet (7.5 meters) from the exterior of the glazing

- Views must be through glass with a visible light transmittance (VLT) above 40%

- Occupants must have direct access to the view and be within three times the head height of the glazing

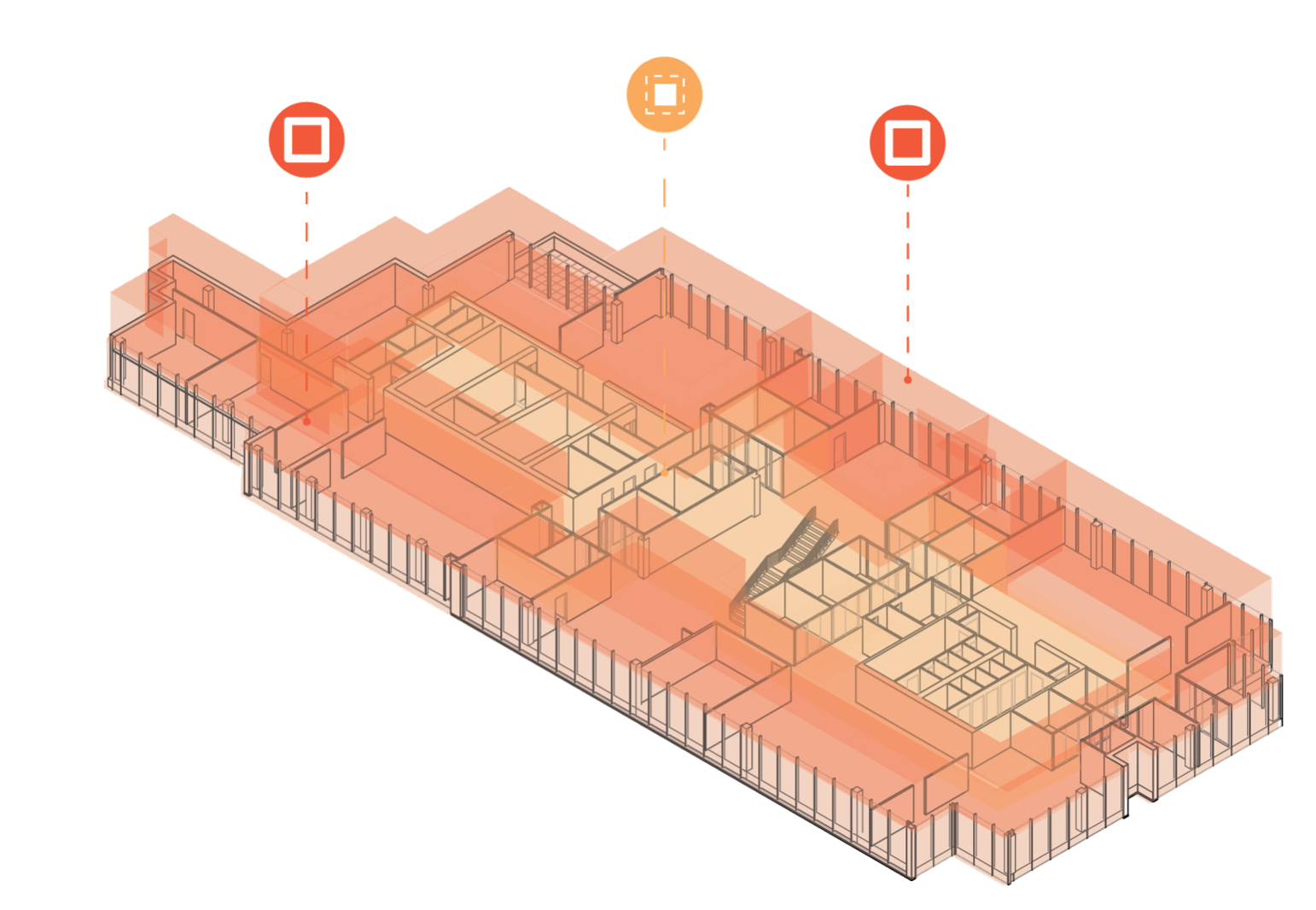

Thermal

Core and Perimeter Zoning

- Ensure that core and perimeter areas are separate thermal zones

- Expand allowable temperature ranges in the perimeter zones to allow fluctuation in response to exterior conditions. Avoid oscillating between mechanical heating and cooling (for example, if core zones control to 70-75 F, perimeter zones could control to 68-76 F)

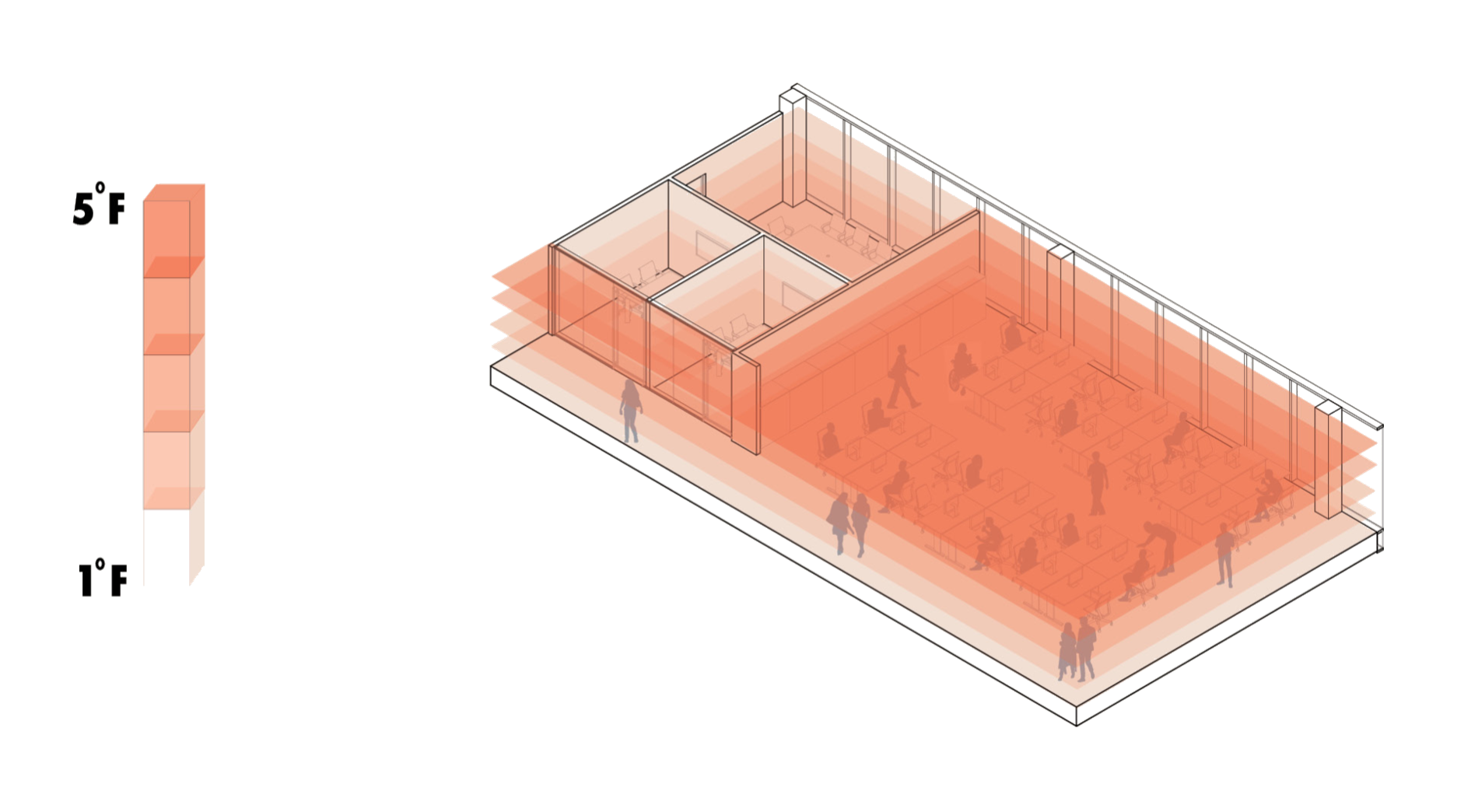

Temperature Shift

- Maintain at least a 5° F or 3° C dead-band between heating and cooling set points to help ensure occupant thermal comfort. A good default temperature range is 70-75° F or 21-24 ° C.

Seasonal Temperature Shift

- Implemental seasonal temperature ranges that adjust up or down 1-2 degrees based on exterior conditions.

Ceiling Fans

- Utilize large ceiling fans to both cool large spaces and facilitate airflow. These large fans are a low-energy option to help increase the thermal comfort of the occupants

NOTE:

The dead-band range temperature drifts and seasonal temperature shifts should be evaluated in the energy model to optimize the energy efficiency.