DC Guide

DISTRIBUTION CENTERS

OVERVIEW

Nike Distribution Centers employ advanced technology and streamlined processes to optimize the movement of products within the Supply Chain - most notably Nike's Logistic System (NLS), a framework unique to Nike. NLS is Nike's approach to design and deploys simple, flexible, and scalable logistics solutions that enable continuous flow and a culture of continuous improvement that empowers people to optimize solutions.

As grounded in NLS, the primary goal within a Distribution Center is to enhance efficiency, visibility, and responsiveness to better deliver on Nike's consumer promise at speed and scale. Every design decision made off the back of these Standards should also be in service of this goal.

Location

A Distribution Center's location will contextualize the proposed design solutions within these Standards. Location can mean both the Distribution Center's position within it's community and the boundaries of the physical site.

Refer to the Location Standards prior to the design of a Distribution Center to best understand context and develop informed design solutions.

Introduction to the

Distribution Center

shopfloor

The Distribution Center Shopfloor typically refers to the physical area where the actual handling, sorting, packing, and shipping of Nike product takes place. This area is often characterized by various operational zones where different tasks related to distribution are carried out.

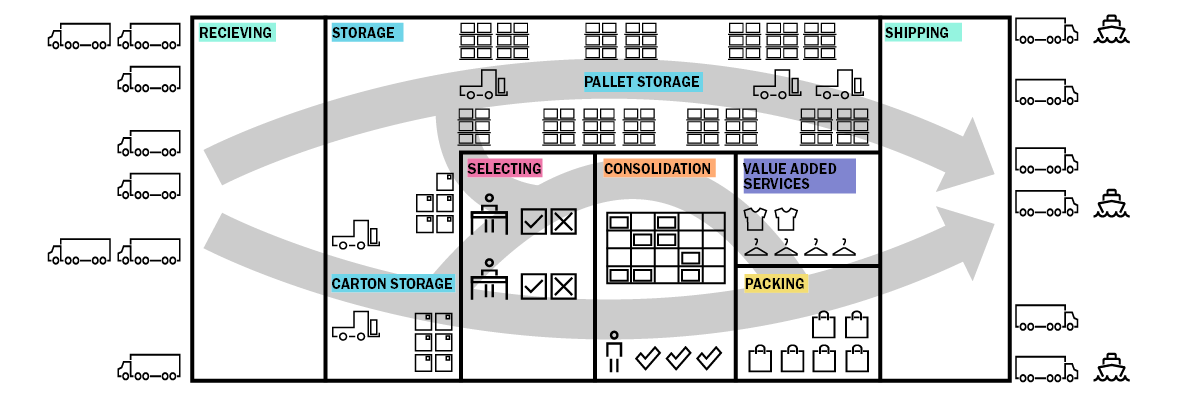

The below diagram demonstrates a simplified Distribution Center Shopfloor. Other methods to familiarize oneself with Distribution Center include:

- Nike Distribution Center onboarding training on Workday

- Working a shift (arrange through HR or local Distribution Center director)

- Visiting the Distribution Center (arrange through HR or local Distribution Center director)

Example Shopfloor layout

- Receiving - inbound trucks are unloaded and inventory is staged for entry

- Storage - inventory is held until it is needed for an order

- Waving - the process by which orders are prioritized and grouped for workflow planning

- Selecting - inventory that make up less than a full carton are retrieved

- Consolidation - the process of marrying up units from around the Distribution Center into a single order

- Value Added Services (VAS) - putting the finishing touches on an order

- Packing - cartons are sealed and shipping labels are applied

- Shipping - cartons make their way to the appropriate outbound truck and directed to customers / consumers

Understanding the

Operational Zone

The Operational Zone is an area specifically designated for performing certain tasks or processes related to the movement and handling of goods.

These zones are organized to streamline operations and often include areas such as receiving, sorting, packing, labelling, and shipping. By grouping similar activities together, Operational Zones help optimize workflow and increase efficiency on the shopfloor.

Additionally, it's crucial to collaborate with Supply Chain on any spaces and work settings within the operational zones to ensure flexibility for accommodating future automated processes and MHE reconfiguration.

Employees within the selecting zone may walk between 10-15,000 steps in a shift, while employees in the consolidation, value add services and packing areas may stand in the one location for a period of time.

All zones where employees may be stationary for prolonged periods should ideally be connected to natural daylight and views, or with adequate lighting to complete the task.